The report presents the stages of development of a computer system for monitoring the technical condition of the sluices with enhanced three-dimensional visualization of the actual and estimated flow patterns the data for which was obtained using 3D laser scanner and deterministic simulation based on the equations of the Rossby.

Analysis of the literature and patent research shows that at the present stage of development of hydraulic engineering there are no counterparts to vortex shaft outletof the Medey mud dam.

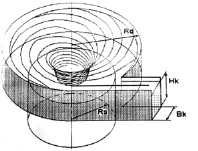

The reference scheme of key parameters of the Medey dam vortex shaft outlet designed by Kazakhstan’s scientific school of hydraulics enables to improve them greatly and set the stage for the creation at the present stage of development of computer tomographyof innovative software products like hydraulic engineering design of hydraulic structures.

It is known that the flow of water in the vortex shaft outlet can be described by the Navier-Stokes equations. These equations are non-linear, two-phase flow (water + stones), the complexity of the boundary conditions for the pressure on the concrete walls of the shaft associated with the occurrence of the effect of «cavitation» lead to the mathematical problems of computational modeling of the flow on the inner surface of the shaft, which requires advanced search approaches to solving these problems.

The known experimental data allows to create a semi-empirical mathematical models based on the search for self-similarity in the vortex shaft outlet flow, taking into account the surface roughness of the shaft, turbulence, hydraulic effects due to the unique construction of the dam vortex shaft outlet swirlers Medey [1].

The further development of the theoretical foundations of technical hydrodynamics of vortex shaft outlet and the creation of innovative software products and calculate the control parameters in the vortex shaft outlet is an important task of modern technical hydrodynamics [2].

Medey mudflow dam originally had 90-meter high ridge, the capacity of the mudflow storage reservoir was 6 million cubic meters, however, as shown, the mudslide in 1973 had a volume of about 5 million cubic meters, and because the water intakes of dam vortex shaft outlet were blocked by the mud at critical moments of the disaster, the reservoir started to overflow so that there were only five meters left to the crest of the dam. Emergency vortex shaft outlet of the first line of the dam are on the left side of the dam, the total length of the tunnel is 540 meters from the cross-sectional area of 16 square meters, inlet tunnel are of square section, vertical vortex shaft outlet is of a cylindrical shape with a diameter of 3,5 meters.

Tangential swirl have a unique design developed and experimentally investigated by S.M. Slisskiy and T.H. Akhmetov [3]. The capacity of the vortex shaft outlet is 30 cubic meters per second.

After the catastrophic mudslide in 1973 there were redundant facilities constructed in the second line of the dam vortex shaft outlet having the total length of the tunnel of 460 meters, the sectional area of inlet tunnel, the diameter of the shaft and vane selected similarly to the first line.The feature of the second line is the water intakes which are constructed from the bottom to the crest of mudflow dam.

Currently the Medey mud dam is reliable shield of the city of Almaty against formidable forces of nature, the capacity of mudflow storage reservoir is 12,6 million cubic meters as well as the seismic resistance of up to 10 on the Richter scale (Fig. 1).

It should be noted that all the experimental data obtained in the laboratory by the personnel of hydraulic structures of Kazakh Energy Research Institute led by Professor T.K. Akhmetov, were collected using Plexiglas models of all sizes, working on a «clean» water.

The left vortex shaft outlet runs in performance mode with a difference of 20 meters for the passage of the flow of the river Small Almaty, the construction can described as reliable and normally operated for nearly 40 years of operation. After the commissioning of the Medey dam vortex shaft outlet no hydraulic studies of facilities and modes of flow in the shaft were performed.

Considering the relevance and practical utility of monitoring the Medey dam vortex shaft outlet, there was organized a research team on the basis of Research Institute of Mathematics and Mechanics of the Al-Farabi Kazakh National University to carry out the funded research project «Computer modeling of the vortex shaft outlet» (162/SF grant of Ministry of Environmental Protection for 2013-2015), which requires to create adequate mathematical and computer models of the operating modes of the dam vortex shaft outlet Medey based on 3D laser scanning using advanced capabilities of computers for animation and rendering processes in the vortex shaft outlet of the Medey dam.

Fig. 1. Medeo mud dam and spillway structures

Earlier work [4] allowed on the basis of Rossby equations to calculate and build,using graphic tools like Turbo Pascal, 3D Max, MatLab 6.5, three-dimensional flow patterns in the structural elements of the vortex shaft outlet of the dam Medey and Bes-Tube waterworks.

For example, in order to build drop structures of Bes -Tyube hydroengineering complex there was a graphical interface designed which allowed to interactively calculate and construct a three-dimensional picture of the flow in a spiral swirl, the data received was practically applied and implemented in the form of a part of hydraulic structures of Bes –Tyube hydroengineering complex (Fig. 2).

Fig. 2. The flow pattern in the spiral swirl

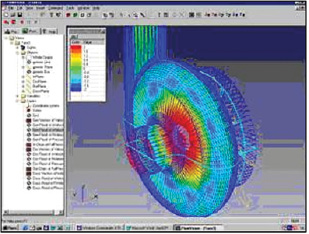

The promising direction in the development of three-dimensional graphical visualization in the Republic of Kazakhstan is the use of FlowVision software system (Russia), the scope of which also applies to the modeling and visualization of three-dimensional computer graphics techniques of fluid flows in hydraulic structures with the definition of the drag coefficients for the effects of roughness. Model problem is the calculation and visualization technology FlowVision [5] hydraulic processes of torus-shaped swirl (Fig. 3).

The widespread use of this software system in Kazakhstan is hampered by lack of license for community use of Flow Vision software system without limiting the number of points on the supercomputers of the Republic of Kazakhstan on loan. In the first phase, the acquisition of Flow Vision software is performed in accordance with a special program of the TASIS for the students «Study student». Participation in this program will allow the International Academy of Business to receive four free 2-month licenses software package for Flow Vision without limiting the number of points for projects within the student’s scientific research of students and undergraduates of the International Academy of Business, however, according to the rules of the TASIS, the rights to publish material in the press were handed over to them. Currently, within the implementation of these projects are carried out numerical experiments with simulated roughness turbulence.

Thus, the mathematical and software base in the field of visualization and animation of hydraulic processes in the hydraulic structures, which allows in combination with 3D laser scanning to conductat the modern level the comprehensive monitoring work of hydraulic structures of the Republic of Kazakhstan using methods of non-destructive quality control of concrete pavement dams, hydraulic processes in the dams, sluices, vortex shaft outlet, predict and evaluate the terms of trouble-free operation of hydraulic structures, there by increasing the safety of hydraulic engineering of hydraulic structuresin case of emergencies.

Fig. 3. The flow pattern in the torus-shaped swirl

The work was submitted to the International Scientific Conference «Modern high technologies» Spain-France, on July 27 – on August 3, 2013, came to the editorial office оn 19.06.2013.