Introduction. The organizational and technological level of modern industrial enterprises is largely determined by the creation and application of effective mechanisms for the formation and implementation of strategic plans for the development and effectiveness of the operational management of all production, logistics and organizational processes that aim toachieve high profitability, development and improvement of production. Therefore, the construction of the organizational structure of enterprise management is a complex multi-level problem [1–15]. Principles and methods of the construction of organizational management structure are directly dependent on many factors. The most significant of these are the specifics of the particular production process the set of technological processes used, production volume, productive capacities used, tactical, technical and quality parameters of the products, the issues of standardization and certification, the qualification level of technical, administrative and management personnel, the management system utilized, the regulatory and legal framework of the enterprise and the organization of internal and external documents. The task of building the organizational structure in an industrial environments a high-priority taskin relation to other problems of industrial process control. Formulation and solution of this problem at a high scientific and technical level is a prerequisite for the effective organization of production, the output of highly competitive products, the growth of financial and economic indicators, dynamic development and continuous improvement of production.

The relevance of the topic is determined by the need to optimize the organizational structure of the enterprise management as the problem of the «upper level» to be the priority decisions as a basic component of a successful and efficient operation of any industrial enterprise, regardless of the type of products and production capacity.

Formulation of the business game framework

The main part of the business simulation game (BSG) includes asimulation model of the environment, the virtual game participants and interaction algorithms between these models and real trainees [1–15]. The BSG body is constructed out of parallel strings of arbitrary algorithmic complexity, one for each party involved in the BSG. The data separation describing the current status of each role type with in this role limits is carried out by means of the fragment, and not at the assembly level of the BSG framework in the structural elements designer.

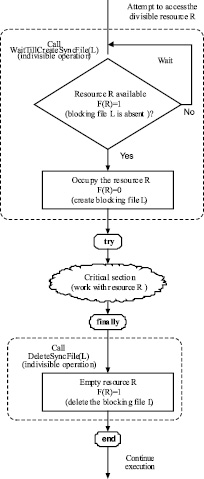

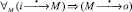

Fig. 1. Mechanism of critical sections based on the blocking variables

The mechanism is similar to critical sections based on the blocking thread when synchronizing the variables in a single process (Fig. 1) [3, 5–8]. To ensure the synchronization process in the local net work, the zero-size file is used as a blocking variable. The presence of the file indicates that the resource is busy, while its absence shows that the resource is available.

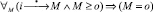

The BSG frame consists of a set of fragments combined into a scenario generated according to the algorithm. The scenario is assembled in a structural elements designer. The framework is intended to form the organizational and structural environment of the BSG as players register in the BSG and its subsequent dissolution when the player leaves the game. For the user, execution fragments of the frame look like a step-by-step wizard, where he/she can terminate the registration process or return to the previous step at any moment (Fig. 2).

Fig. 2. Schematics of the BSG frame work

Fig. 2 legend: rij – fragments that implement the scenarioi-throle; try ... finally ... end – exceptions handling at the level of the BSG scenario; it provides guaranteed performance of de-initializing fragment of the frame.

Some fragments constituting the frame are visual and are intended forvisual organization of the User Interface during the registration of the player in the BSG. Other fragments are no visual and are designed to perform as a support for the operation of the BSG frame.

It is possible to organize the parallel execution of the processes within a given game set to reduce the delays associated with performing lengthy operations (e.g. being in the waiting regime). In this case, the non-visual (auxiliary) process will run in the background. The main thread of the scenario and auxiliary processes can interact(communicate) and sync. Background processes can also interact with each other.

The formulation of the technological processes in terms of Petri nets

Most of the operations of the technological process share resources. Execution of the operations is partly synchronous and partly asynchronous. Hence, in addition to the above description, a model describing processes in the form of Petri nets is suggested [3, 5–8]. These network models of the processes are the basis for the description and the scenario execution of an interactive simulation model (IMU). They allow to check whether the framework is correct, to identify the presence of dead ends and blockages in its description; as well as to identify possible options for further development of the simulated technological process at an early stage while training the personnel and in the process of simulation itself.

There are additional restrictions for a given type of Petri nets:

A4.  if

if  , that is relation F+ (transitory closure of F) is not symmetric and the network does not contain loops.

, that is relation F+ (transitory closure of F) is not symmetric and the network does not contain loops.

A5.  is finite. This limitation requires that any net work representing the process should not have an on-emptyset of main places and does not contain‚ infinite’ paths.

is finite. This limitation requires that any net work representing the process should not have an on-emptyset of main places and does not contain‚ infinite’ paths.

A6.  , that is any transition has at least one entrance and one exit.

, that is any transition has at least one entrance and one exit.

A7.

Such net work processes have a standard initial layout where only head-points contain one token.

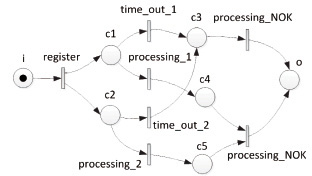

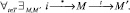

Let’s consider the net works hownin Fig. 3. It is clear that the description of this particular BSG scenario fragment, simulating the processing of incoming complaints, has several disadvantages. If transitionstime_out_1 and processing_2 or transitionstime_out_2 and processing_1 are executed, then the final result of the network performance will be incorrect, because the token will remain in the position c5 or c4. If transitionstime_out_1 and time_out_2 are executed then the processing_NOK operation will be performed twice and because there are two tokens in the position o the time of completion is unclear.

In this work we show that the process description should meet the following criteria:

1) Network has entrance position i (initial condition) and exit position o (final condition);

2) Each operation/condition is located on the path from i to o.

3) For any sample of technological process the performance of the network should have an end and at the end point the chip is at the position o and all the other positions are empty;

4) There should benodead-end operations in the net work. That is it should be possible to perform any type of task at the corresponding path of the Petri net describing the technological process modelled in the simulation game.

Fig. 3. Petri net for processing the incoming complaints

Fulfilment of the first two criteria can be checked by using methods of statistical analysis, that is they exclusively have to do with the structure of the Petri network. The other two additional limitations correspond to the so-called property of defect lessness of the network.

A process modelled by the Petri net PN = (P, T, F) is considered defect free iff

1) For each state M reachable from the state i there is a sequence of execution of transitions leading from the state M to state o. Formally

(Here symbol I denotes both the position I and the state with the only token at the position i)

2) State o is the only reachable state from the state i with at least one token at the state o.

Formally,

.

.

3) There are no dead-end transitions in (PN, i).

Formally,

.

.

The property of defect lessness corresponds to the dynamic behaviour of the net describing the technological process and can be used for the analysis of their correctness in the composition of the BSG scenarios.

The above-given description of the Petri net allows us to investigate the topology of the BSG scenario, to find loops and dead ends. In addition, the matrix description of the resulting Petri nets can find invariants of the network, which allows us to solve the problem of finding all the variants of the simulated process in the course of an educative game with the use of the simulation game.

Conclusion

In conclusion, the principles of the scenario construction and instruments of the BSG were developed. We proposed network models of the technological processes that form the basis of the description of the interactive simulation scenario and allow us to check the correctness of the scenario, to see the presence of dead-ends and blocks in its description. Also they allow us to identify possible options of the development of the simulated technological process at the early stages of the game.

It was shown that it is possible to transform formal description schemes of the technological processes into a multipart BSG scenario automatically similar to the usage of the critical sections based on the blocking variables during the syncing of the flows of a single process.

The work is submitted to the International Scientific Conference «Science and education integration», Maldive Islands, February, 14-21, 2014, came to the editorial office оn 11.12.2013.