The discussion between national research schools about benefit and harm of beer doesn’t cease.

Recently the German public tends to transfer consumers to non-alcoholic beer [1] whereas in Scotland there is a prevailing tendency of superstrong beer production (Armageddon with a strength of 65 % and Snake Venom with a strength of 67,5 %), received by modern technology of cold («frosty») distillation [2].

The domestic modern medicine saved up statistically reliable information about evolution dynamics of «beer alcoholism» among just as children so teenagers [3; 4; 5; 6].

Considering known information about the target organs, damaged by beer microimpurities, we developed and patented the technology of producing beer possessing tyre-tread properties [7]. The main point of a proposed technical solution is to add the biological active agents having tyre-tread effect on target organs in pharmacological significant doses in ready beer. We established that entering of adaptogenes, hepatoprotektors, antioxidants and anti-carcinogens in combination with plasmolyzate of the fulfilled beer yeast doesn’t distort a typical flavor-aromatic bouquet of real beer brands. Thus the biological value of beer which we suggest to estimate on the general mineralization (the bottom ash), total vitaminization (concentration of seven vitamins) and on a prebiotic saturation (the maintenance of the dry rest) increases.

Now we develop a complex of scientific and technical decisions to eliminate getting in ready beer the most toxic microimpurities, characteristic for classical technologies of brewing.

Having analysed in brewing actual practice life cycle of beer production by means of technological testing on typical lines we established, using the principles of HACCP, three main critical control points demanding monitoring and modernization of technological process stages: raw grain storages, hop and mash boiling, and also the organization and carrying out the main (basic) fermentation.

Raw grain storage

Still the problems of the ready beer safety caused by the presence of field microbiotas and by diseases of raw grain storage aren’t solved. The experience of the Danish brewers, who tried to fight against field microbiotas by methods of before-storage grain disinfection, appeared to be inefficient and fraught with injection of chemical toxicants into grain raw material. Also the existing methods of deratization and disinsection, and as well as grain treatment in storages appeared to be inefficient. Preparations of copper, mercury and organochlorine compounds are capable to strengthen even more the load on a liver and other bodies of the organism detoxication system. However the untreated brewing grain raw materials is the reason of emerging of aflatoxins, ochratoxin A, deoxynivalenon and others contaminants in ready beer [8].

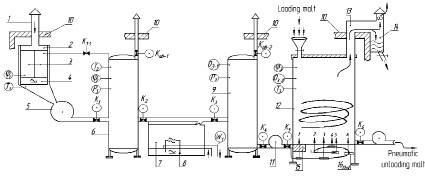

We developed the device of grain brewing raw materials sterilization on the initial stage of brewing that excludes the possibility of getting the grain microbiotas toxicants in a mash (Figure).

The periodic ozone-aired drying and grain sterilization before crushing allow to lessen the number of microbiotas on 3–4 levels (Table).

The application of the method will allow to remove the question about permissible norms of beer pollution by mycotoxins and others contaminants: there just should not be any aflatoxins and enterobakteria in beer. We suggest to consider their detection in any volume of test as processing deficiency. The offered method is applicable in fight against diseases of grain storage as well as at elevators instead of an existing energy consumptioning thermal drying.

Micronization efficiency indicators

|

Treatment method |

Time, sec |

Moisture content, % |

Starch, % DS |

Dextrines, % DS |

Reducing sugars |

Amine nitrogen, mg/100 g |

|

Extrusion |

12 |

9,5/14 |

57,8/60,5 |

8,2/0,1 |

6,58/1,2 |

47,5/39,6 |

|

Barohydrothermal treatment |

10–50 |

12,6/12,1 |

50/62,0 |

– |

0,6/0,31 |

47,4/39,4 |

|

Micronization |

30 |

27/11 |

44/55 |

6,8/0,09 |

1,22/0,61 |

– |

Notes:

1. Post-treatment indicators are given in a numerator, indicator value of a control sample is given in a denominator;

2. DS – dry solids.

Hop and mash boiling

Long ago it is proved that liver injury among beer fans happens not from excess of alcohol, but from ions of copper which diffuse under the influence of alcohol and acetic acid from copper surfaces of being cooled tubes and filtration sieves and which is dissolved in fermenting mash. The replacement of all copper details in the processing equipment is recommended for process “improvement”, as well as it is forbidden the application of the technological additives containing formaldehyde or cobalt salts. World experience showed that the process of hop and mash boiling itself inevitably increases the toxicity of beer. It is established that during hop and mash boiling, except formation of psychotropic connections, hard resins pass from hop to beer. These hard resins are responsible for rectum carcinogenesis at 5 % of beer fans.

Considering the world tendencies of brewing [9] directed on using the potential of monomeric heterocyclic polyphenols of hop and hop products, to which flavonoid xanthohumol possessing the expressed anti-virus properties belongs, we developed a construction of a brewing copper and boiling modes, allowing to save useful properties of hop oil preparations, first of all, of xanthohumol. The developed construction of a low-temperature brewing copper with a total automation equipment allows to operate in an automatic mode the mash quality at essential lessening in energy consumption on boiling and the subsequent mash cooling (patent 97130) [10].

Organization of the main (basic) fermentation

Our research showed that today the process of the main fermentation is impossible mixture of two biotechnological processes demanding for optimization of various biological functions by yeast mutually exclusive technological conditions: aerobic high-temperature (+35 °С) conditions for yeast biomass growth and anaerobic low-temperature (from +4 to + 8 °C) conditions for yeast glycolysis realization. We developed the optimized designs of the propagator for reproduction of seed yeast (patent 98001) [11] and of the main fermentation tank (patent 2423417) [12] and proved the management criteria of these processes. Namely: the process of reproduction should be carried out before the reaching of the yeast residual quantity necessary for ethanol production in the set volume during the glycolysis process. Plus the ratio of concentrations alcohols/carbohydrates is supervised and regulated automatically and defines finishing dates of the main fermentation, at that fractional addition of demanded amount of carbohydrates prevents the formation of toxic BPF (by-product fermentation) because of an inevitable polyauxy at deficiency of sugars.

Increase of biological value of beer

We suggest to use widely the new technical solution providing the content increase of the bio-elements, vitamins and biologically active agents in beer and consisting in addition into beer 3–8 % cooled native plasmolyzate of the fulfilled beer yeast (TS 9184-001-56090574-2012) [13]. Thus in the quality standard of beer recommended for the WTO countries we offer following content norms of the bottom ash not less than 1,8 g/dm3, the dry rest not less than 50 g/dm3 and the total content of seven vitamins not less than 9,46 mg/dm3 at average concentration of vitamins and vitamin-like connections about 210 mg/dm3 [14].

Summary

The decrease of toxic influence of beer microimpurities on target organs and functional systems of consumers can be provided technologically. The technology of the brewing process improvement, including ozone-aired sterilization of grain brewing raw materials, low-temperature mash boiling without hop and the modification of the main fermentation with the prevention of toxic by-products accumulation is offered.

We consider the optimum decision, excluding entering of mycotoxins and enterobakteria in ready beer, the necessity of the ozone-aired sterilization of grain brewing raw materials. The low-temperature mash boiling without hop will allow to exclude the contact of the consumer with the hop cancerogenic hard resins whereas the management modernization of the main fermentation will allow to lower possibility of toxic BPF (by-product fermentation) formation. The application of the fulfilled beer yeast plasmolyzate into beer allows to provide the increase of biological value of beer.

The research is executed with the financial support of the Russian Foundation of Fundamental Research and the Government of the Orenburg region (No. 13-08-97059 a (r).