The cement paste modified with carbonate filler hardening kinetics investigated. The following conditions taken into account: the content of carbonate filler varied from 0 to 35 %, the content of superplasticizer Glenium®51 was 0.5 % of cement weight. Found that when the self-sealing cement pastes carbonate filler content reaches 12 % modified cement stone strength does not reduce. The cement pastes with up to 35 % carbonate filler content increasing get 16 % compressive strength reduce. The carbonate filler content increase up to 35 % of a mixed binder weight does not retard the strength kinetics growth. After 3 days compositions gain 80 %, and after 7 days – 90 % of the 28 days strength. The self-compacting concrete compositions carbonate filler application is aimed to the rational use of local mineral resources and reduce the construction cost.

At present, much attention is practically paid to the rational and the integrated use of the local mineral resources, production, and distribution of the environmentally friendly building products challenges. The local mineral resources application is reduced the transportation costs and the construction projects ones. In particular, the long – term integrated use of the environmentally friendly carbonate rocks screenings crushing, which are widely prevalent in many regions [3]. So, the soft carbonate rocks’ grinding is not required a lot of energy consumption. The grinding product, as the filler, can be used in the cements’, concretes’, and dry construction mixtures’ compositions [4]. It, moreover, quite well known, that the calcite and dolomite are exhibited high level adhesion to the cement paste. That is why, many researchers have already noted, that high level is the consequence of their physical and chemical interactions at the phases’ boundary interface [2, 3, 5].

In the self – compacting concretes’ compositions, the number of the carbonate filler amount administrated may be further increased, in comparison with that is present in the cement. The study of the carbonate filler content influence in the cement on the growth kinetics of the self – compacting mixtures strength is presented itself the special interest. So, the carbonate filler content further increase should not to be led to the significant reduction in the strength, as well as slower growth kinetics strength of the mixed and blended cement [1].

The Purpose of the Study. Thus, the purpose of the study – is to be determined the filler use efficiency and its effectiveness from the local carbonate rocks in the compositions of the self – compacting modified cement pastes. The main objective was to study the content impact of the carbonate filler on the strength formation and the self – compacting cement pastes’ hardening kinetics, having modified by the «Glenium®51» super-plasticizer.

Materials and methods of research. As the binding material, the clinker Portland cement, with the specific surface area 350 m2/kg, has been used. The clinker’s mineralogical composition has been, as the following: C3S = 59 %, С2S = 16 %, C3A = 8 %, C4AF = 13 %. The carbonate filler has been obtained by the grinding crushing screenings of the carbonate rocks, having consisted of the limestone and the dolomite. The dolomite content has been made up 81 %. The carbonate filler has been milled up to the specific surface area 350 m2/kg. The calcareous filler has been used, as the aqueous slurry.

As the modifying additive, the «Glenium®51» poly-carboxilate super-plastilizer of the «BASF» company has been used. The self-compacting cement pastes have been prepared, with the 125 ± 5 mm blirring, when tested in the Hagerman cone from the cement mixture, the carbonate filler, water, and the «Glenium®51» super-plastilizer additive, in the amount of 0,5 % from the cement weight. The samples, with their 20×20×20 mm size, have been molded from the cement pastes. Then, the samples have been hardened in the water at 20 ± 2 °С temperature. The compressive strength of the modified cement paste has been determined after the 3, 7, and 28 calendar days.

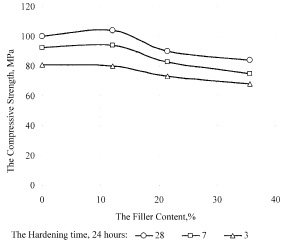

Results of research and their discussion. The composition, the strength results of the study, and the hardening kinetics of the modified cement pastes, depending on the carbonate filler content, have already been given shown in the Figure and in the Table.

Thus, it has been determined, when the content in the cement is up to 12 % carbonate filler, the modified cement paste strength is not practically reduced. The obtained result is explained in the minor changes of the aqueous cement and the aqueous solid ratios, in comparison with the composition on the clinker cement. The further increase in the carbonate filler content in the two – component cement from 0 up to 35,5 % is accompanied by the growth of the aqueous cement ratio of the self-compacting modified cement pastes from 21,75 up to 33,15 %, and, moreover, by the compressive strength decrease of the cement paste for 16 %. The carbonate filler content increase up to 35 % by the two-component binder weight is not slowed the strength growth kinetics. So, after three calendar days (e.g. 72 hours) the compositions are being gained 80 %, and after 7 days (e.g. 168 hours) – 90 % from the 28 day (e.g. 672 hours) strength.

The Growth Kinetics of the Compressive Strength of the Self – Compacting Modified Cement Pastes, Depending on the Cement Carbonate Filler Content

The Cement Pastes Composition with the Carbonate Filler and the «Glenium®51» Super-plasticizer (e.g. 0,5 % by the Cement Weight).

|

Number Composition |

The two – component (mixed) cement composition |

Aqueous cement ratio, % |

Aqueous solid ratio, % |

The ultimate compressive strength, UCS, 672 hours |

|

|

Clinker cement, % |

Carbonate filler, % |

||||

|

1 |

100 |

0 |

21,75 |

21,75 |

100,0 |

|

2 |

88 |

12 |

22,65 |

19,78 |

104,0 |

|

3 |

78,5 |

21,5 |

25,85 |

20,25 |

90,0 |

|

4 |

64,5 |

35,5 |

33,15 |

21,39 |

84,0 |

|

5* |

100 |

0 |

25,00 |

25,00 |

71,3 |

Note. The composition 5* – is the control one, it is corresponded to the normal density, and it is contained no «Glenium®51» additive.

Conclusions

The integrated application of the «Glenium®51» additive and the carbonate filler, in an amount of 12 %, as the part of the self – compacting cement pastes, has been given the positive impact on the strength formation and the strength growth kinetics of the cement paste.

The carbonate filler application in the compositions of the self – compacting cement pastes is promoted the rational use of the local mineral resources and, moreover, the cost reduction of the construction.